Business Areas

Manufacturing Industry

Powder Conveying Equipment

Business Areas

Manufacturing Industry

Powder Conveying Equipment

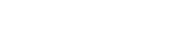

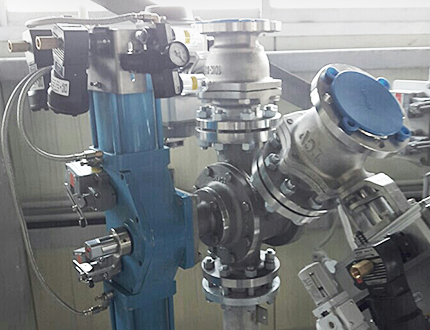

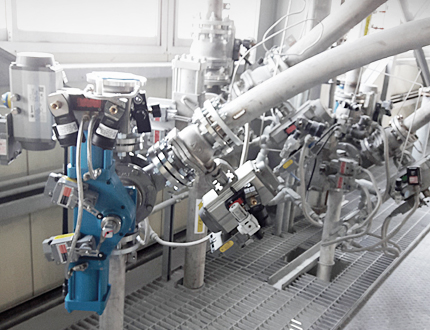

Pneumatic powder conveying equipment transports powders and solid particles using gas (nitrogen, oxygen) through various types of pipelines.

It is the most effective way to control the transfer of powders or particles to and from silos, hoppers, pneumatic conveying equipment, bag filters, cyclones, etc. This is essential infrastructure for supplying large quantities of products in precise quantities, depending on the characteristics of the raw materials, in the petrochemical and processing industries.

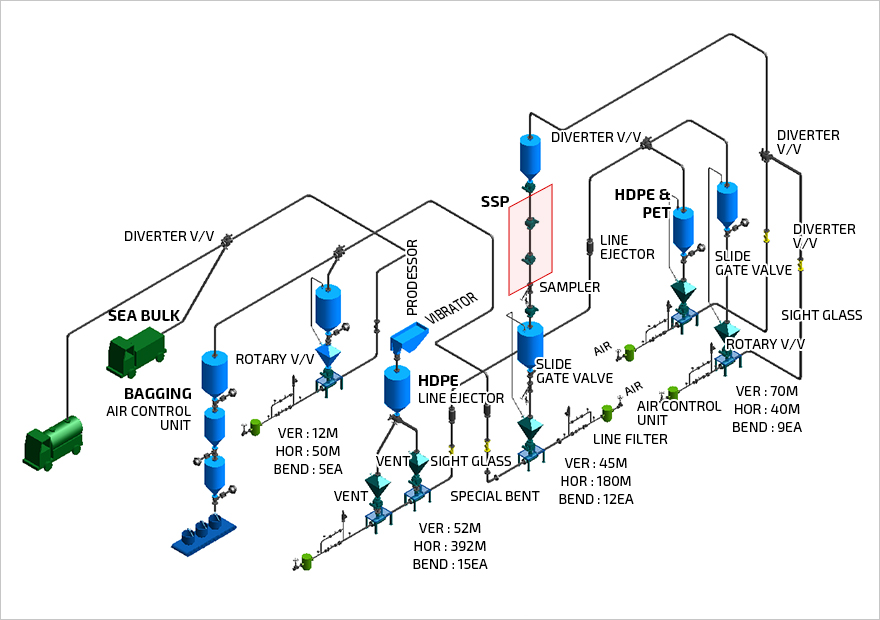

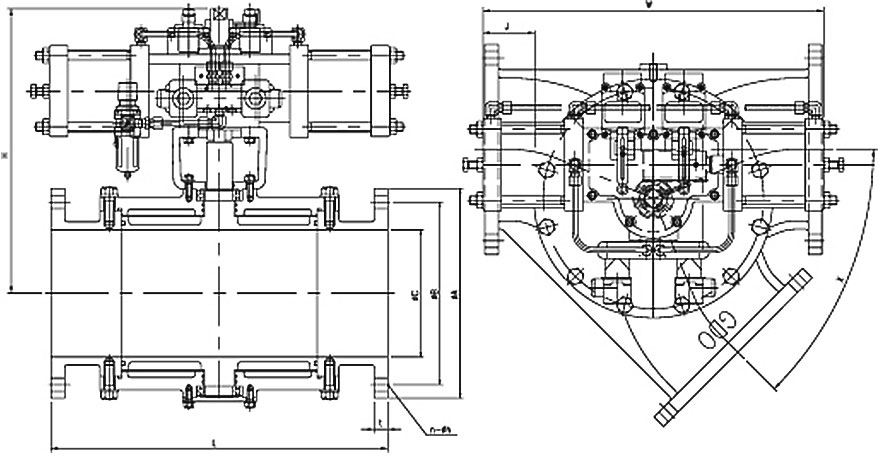

Widely used to change the direction of flow in plug-type equipment that pneumatically transports powder and particles.

Silos are essential equipment for processing and manufacturing in all industrial sites requiring long-term storage of liquids, such as petrochemicals and refined products, as well as powders such as cement and grains without packaging.

A bag filter is a device that separates dust and clean gas.

A cooler is installed at the rear of the compressor or blower to cool the heated air or gas.